Hammerhead™ Testing Documentation

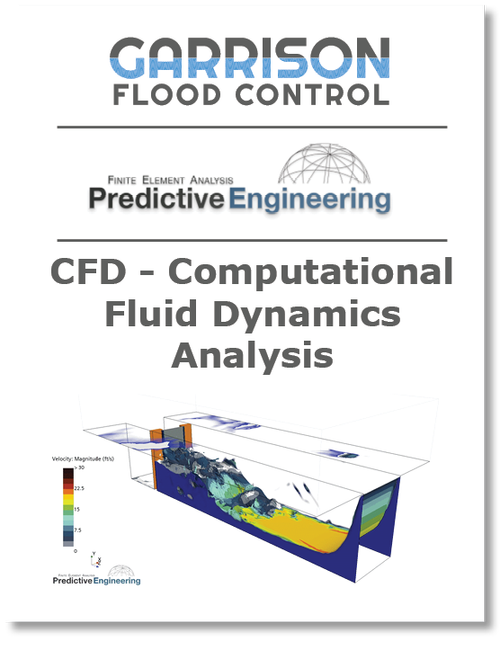

The proper engineering of flood walls should be an essential factor in determining which type of flood protection system to implement. The use of flood walls in flood prevention has become widespread due to the need for advanced flood protection solutions and the rise in the frequency of severe storms and weather events. These flood wall systems differ in terms of materials, deployment, installation methods, and overall efficacy.

The testing of flood walls encompasses a diverse range of methodologies aimed at comprehensively assessing the barrier’s expected performance under expected stressors. This process generally focuses on examining the characteristics of the materials used in the construction of the flood wall and its components, and utilizing knowledge about the material’s yield strength to determine its capabilities to resist flooding.

To thoroughly gauge the impact of hydrostatic pressure exerted upon the system, when confronted with rising floodwaters, one must calculate the materials poisson ratio and yield strength through physical testing and then compare that to the calculated pressure exerted by water at varying depths.

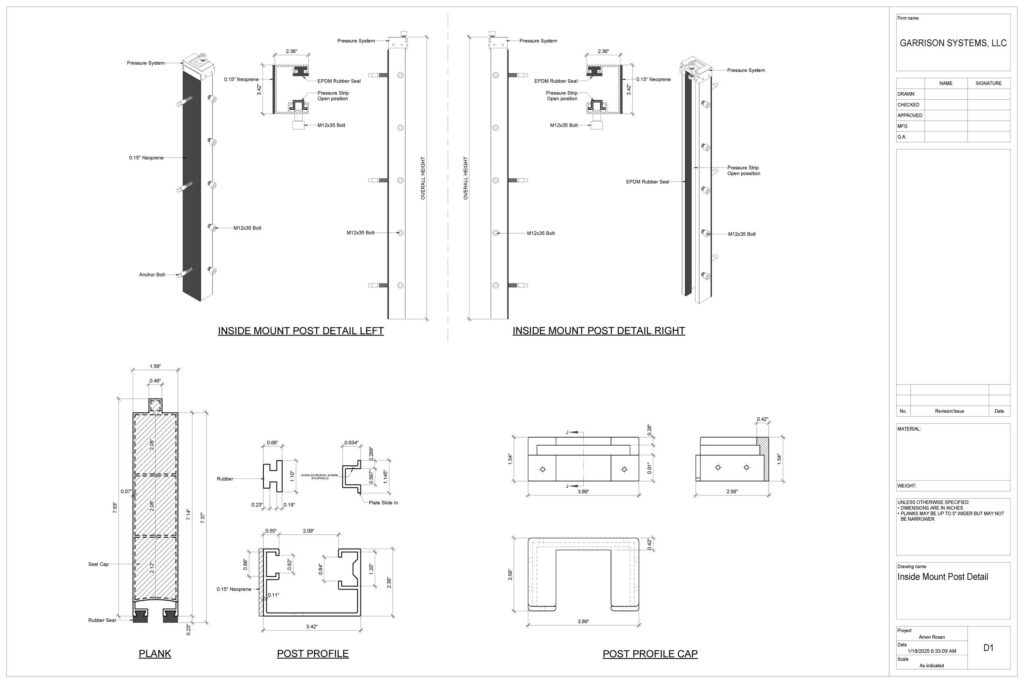

Specifications

Planks

- Plank Material: 6063 T-6 Aluminum

- Plank Width: Varies Depending on Opening Size

- Plank Weight: 2.016lbs per ft.

- Individual Plank Height: 7.37” (18.7cm)

- Plank Depth: 1.58” (40mm)

- Plank Extrusion Wall Thickness: 0.0787” (2mm)

- Sealing Strip Material: Rubber EPDM

- Tallest Protection Height: 6.14ft (10 planks

Posts

- Post Material: 6063 T-6 Aluminum

- Post Height: Varies depending on number of planks

- Post Depth: 3.94” (10cm)

- Post Width: 2.36”

- Post Weight: 3.025lbs per ft.

- Middle Post Width (Double Channel): 5.12”

- Middle Post Depth: 3.94” (10cm)

- Middle Post Weight: 6.05lbs per ft.

- Sealing Material: Rubber EPDM

- Bolts: M12 8.8mm bolt